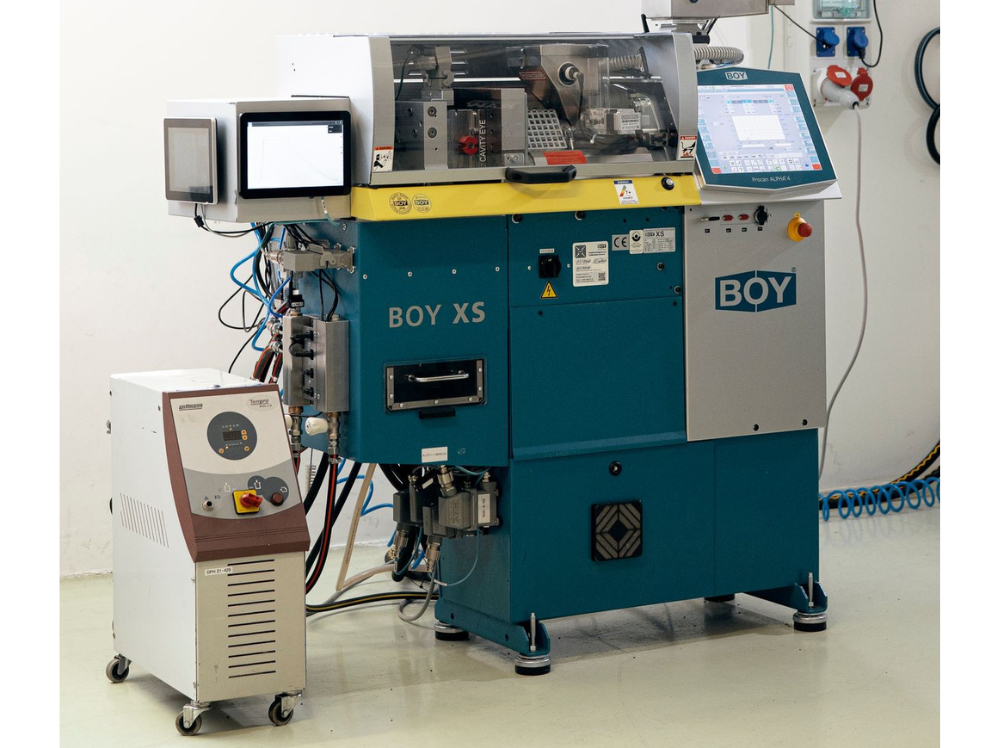

WinInMo presenting its network during Innovation Day at Wirth

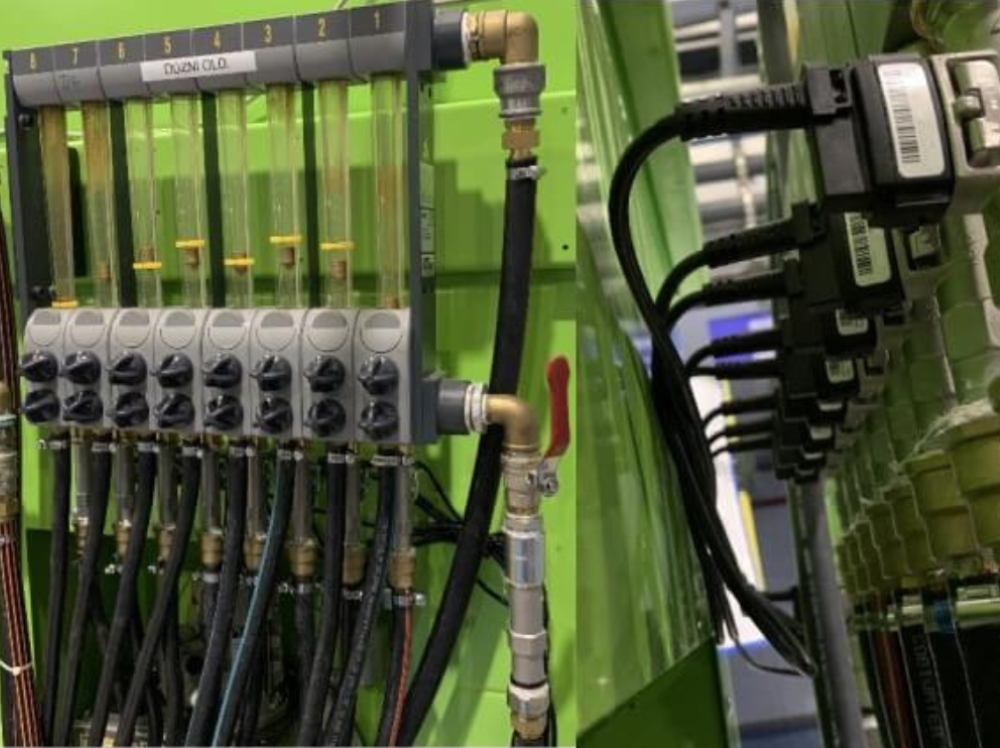

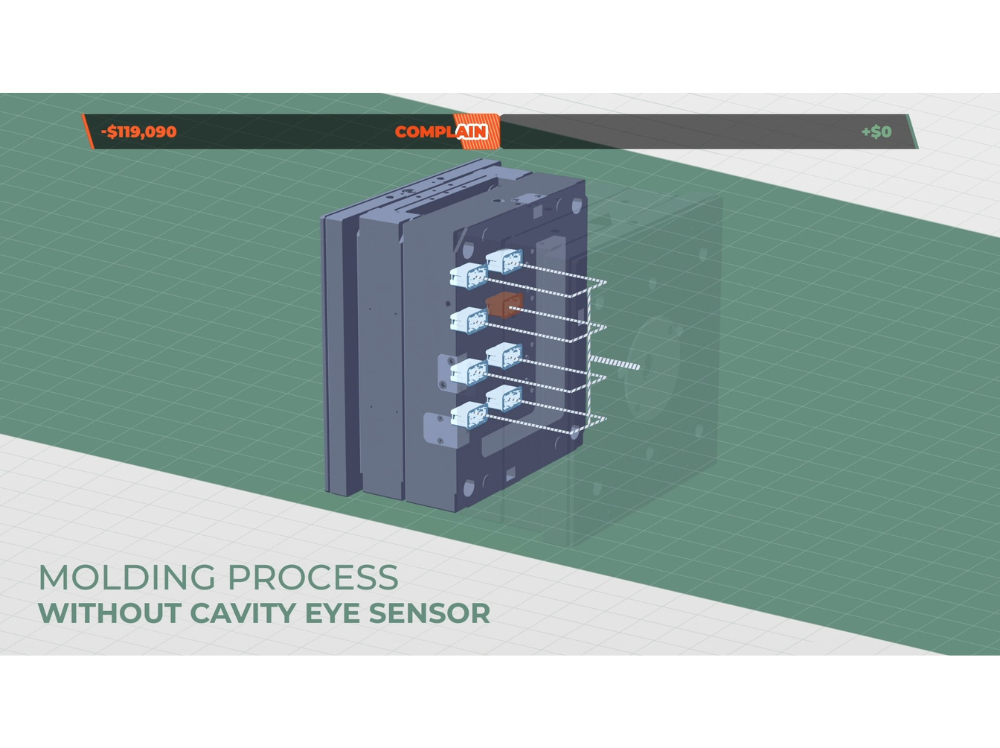

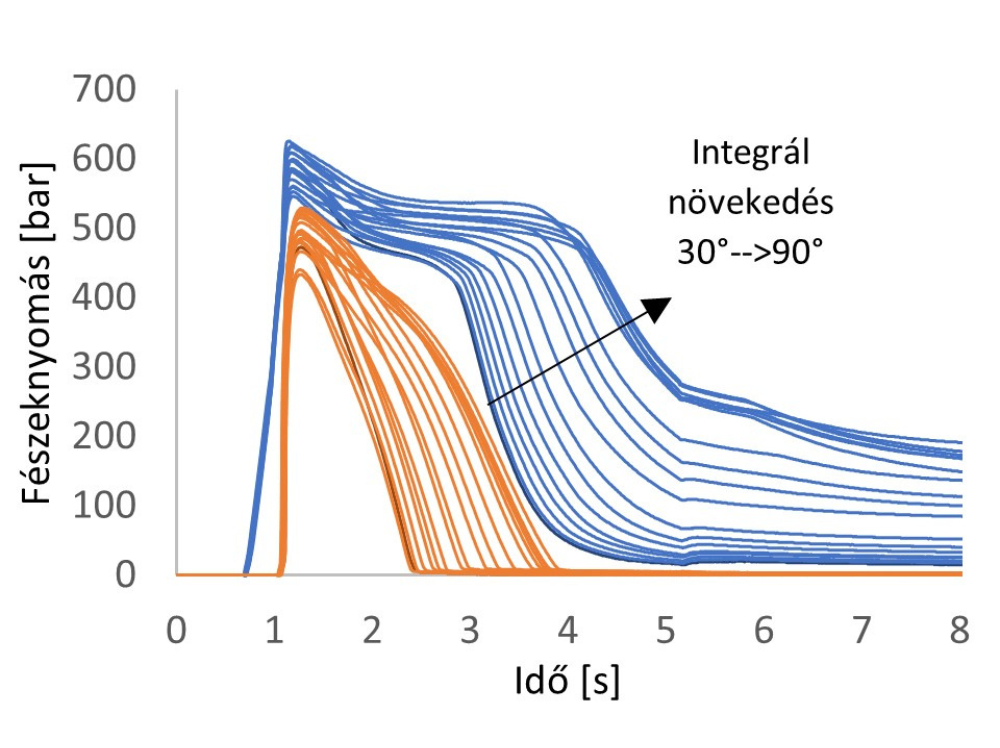

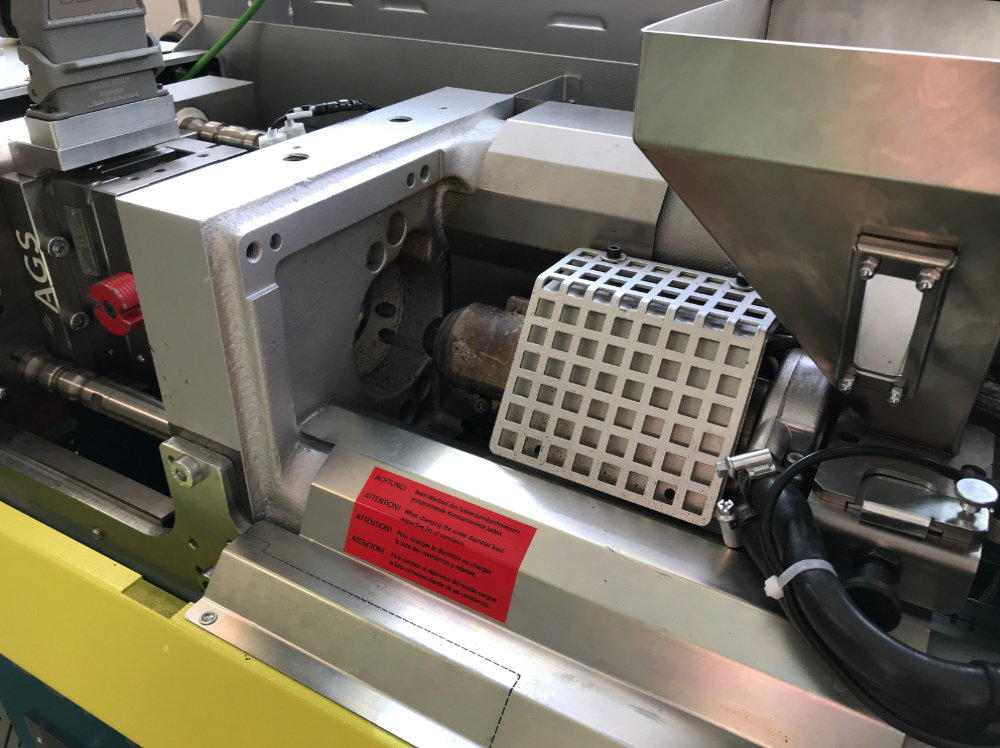

The network "WinInMo" develops solutions for a sustainable and permanently reliable injection moulding process. Goals include energy savings, optimmalization of heating and temperature control circuits and the operational reliability of cooling water circuits. This requires a new conception and development of the thermal installation space, the cooling water treatment and online monitoring of all process parameters. Developments with new biogenic plastics open up additional future market opportunities. CAVITY EYE provides the visualization of the process parameters and supervises the entire injection moulding process.